Acoustic Material Flow Sensors

Effectively measure material flow in the most challenging and important environments.

Appareo is a pioneer in the development of acoustic material flow sensors. Our flow sensors are excellent at measuring the flow of pneumatically driven granular particles.

Appareo’s Flow Sensors

For operations where granular material like seed or fertilizer is being propelled by air through a system, being dragged through a system, or falling through a system, Appareo sensors provide a robust way to reliably measure the material’s flow. This capability can be deployed in manners that are not invasive and is especially useful in very challenging environments like:

- Dust-ridden or cloudy environments

- Caustic or corrosive environments

- Very high vibration environments

For many applications in which Appareo has deployed sensors like this, it has previously not been possible to deploy an effective, accurate, and cost-effective sensor to monitor important machine functions.

Technology Application

Although currently used in agricultural applications, these sensors could also be used to measure the flow of other particles like aggregates. The sensors themselves are purely mechanical and contain no moving parts. These sensors are designed much like a stethoscope, with a surface that the material impacts, an auditory tube leading back to the electronics, and a microphone within the electronics that measures the energy transferred by material striking the surface of the sensor.

Appareo’s signal processing expertise is leveraged to process these sensor inputs in ways that allow the sensors to be used in a broad range of sensing applications without requiring recalibration, despite changes in particle size and speed. Examples for the utilization of this sensing principle to solve challenging monitoring and control problems is discussed in three different examples below: Seed and Fertilizer Flow Sensing in Pneumatic Seed Drills or Air Seeders, Material Sensing in Combines, and High-Flow Fertilizer Flow Sensing in Self-Propelled Spreaders.

Seed and Fertilizer Flow Sensing in Pneumatic Seed Drills or Air Seeders

In one embodiment of this sensing principle, Appareo designed a material flow sensor for Intelligent Ag Solutions. This sensor is used to measure the flow of seed and/or fertilizer through an air seeder. The sensor ensures that the seed and fertilizer reaches the ground and no impediments in the airstream cause uneven distribution or blockage of material.

In this application, the sensor is a significant improvement in reliability over electro optical sensors because fertilizer (which wants to absorb water and cake onto sensors) and dust can accumulate throughout the machine during the season in which it operates. This fouls traditional optical sensors, causing false or missed readings. This sensor has been very successful and reliable in this challenging environment.

Material Sensing in Combines

These sensors, which are highlighted in this video from AGCO, are positioned throughout the separation system. The sensors, in their design, construction, and material selection, are optimized to sense the strikes of the seeds against the membranes of the sensor, providing a good signal-to-noise ratio, despite the amount of plant matter also moving through the combine harvester.

Further, Appareo developed the mechanics of the sensor to produce a signal output that is significantly outside of the noise profile of the machine itself, ensuring that the machine noise does not pollute the sensor signal.

High-Flow Fertilizer Flow Sensing in Self-Propelled Spreaders

Measurement of fertilizer is an important and challenging thing to do in agricultural applications. Fertilizer is highly corrosive and is hydrophilic, meaning that it wants to absorb water. When it does — for example, in high humidity air — it will stick to things and rapidly begin to corrode many materials.

Some fertilizer is spread using self-propelled machines that are commonly referred to as floaters. These machines drive quickly over the ground while fans propel material through an airstream against a deflector, which spreads the granular fertilizer on top of the ground. The machines can operate over a very broad spectrum of rates and speeds, requiring a sensing solution that can handle a large range of signals in a very challenging working environment.

To solve this problem, Appareo developed a sensor that adheres to the back of the deflector, named Recon SpreadSense.

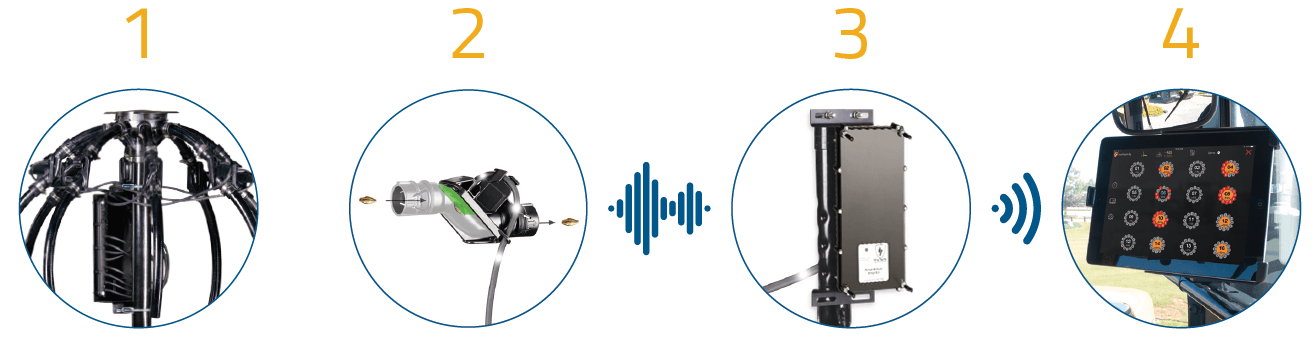

This approach allows the sensor to easily be retrofitted to machines, does not disrupt the normal flow and distribution of material, and provides a high quality flow signal. The sensor measures the transfer of energy from fertilizer striking the deflector and the resultant signal is read by Appareo-designed electronics and broadcast to a monitor in the cab of the machine. This allows the machine operator to effectively monitor the proper operation of the machine, ensuring fertilizer is properly applied to maximize crop yield.