Smart Cameras & Optics

Custom design and manufacturing of smart cameras and optical sensors

for rugged environments, using Appareo deep neural networks for machine learning.What sets Appareo apart is the ability to fully integrate optics with real time processing for rugged environments.

Flexible Configuration

Imagery/lens combinations and custom mounting are critical for maintaining image quality and focus in high-vibration and extreme temperatures. Appareo customers can ensure quality image capture in the most extreme off-road environments.

In addition, Appareo’s ability to integrate custom machine learning algorithms — including scratch-built convolutional neural networks — enables sensors to be an AI at the edge (onboard the machine without cloud computing) to quickly generate value-added solutions.

Combine Grain Quality Sensor

For AGCO Corporation (NYSE:AGCO), Appareo developed an optical sensor for the evaluation of grain quality in a combine harvester. The sensor uses 12 multispectral LEDs capable of producing over 2,300 lumens of instantaneous illumination. Using a microphone inside of the camera system, the sensor learns the paddle pass frequency of the clean grain elevator and times the illumination of the sample to capture data as the grain is flung from the paddle of the clean grain elevator. This unique capability allows for more flexibility in the sensor’s mounting location, with capabilities to be located in areas where material may be moving quickly through the harvester.

The optical data is presented to a processor for algorithms, either conventional or machine-learning based, to evaluate the amount of cracked grain and material other than grain (MOG) in the sample. Information on the quality of the grain sample can then be sent over CAN bus or Ethernet to other electronic devices or for presentation to the user. Although only used currently to detect crackedness and material other than grain, Appareo has successfully demonstrated the ability to detect other grain properties, like moisture, on this sensor as well.

Identification of Grain Types using Smart Optical Sensors

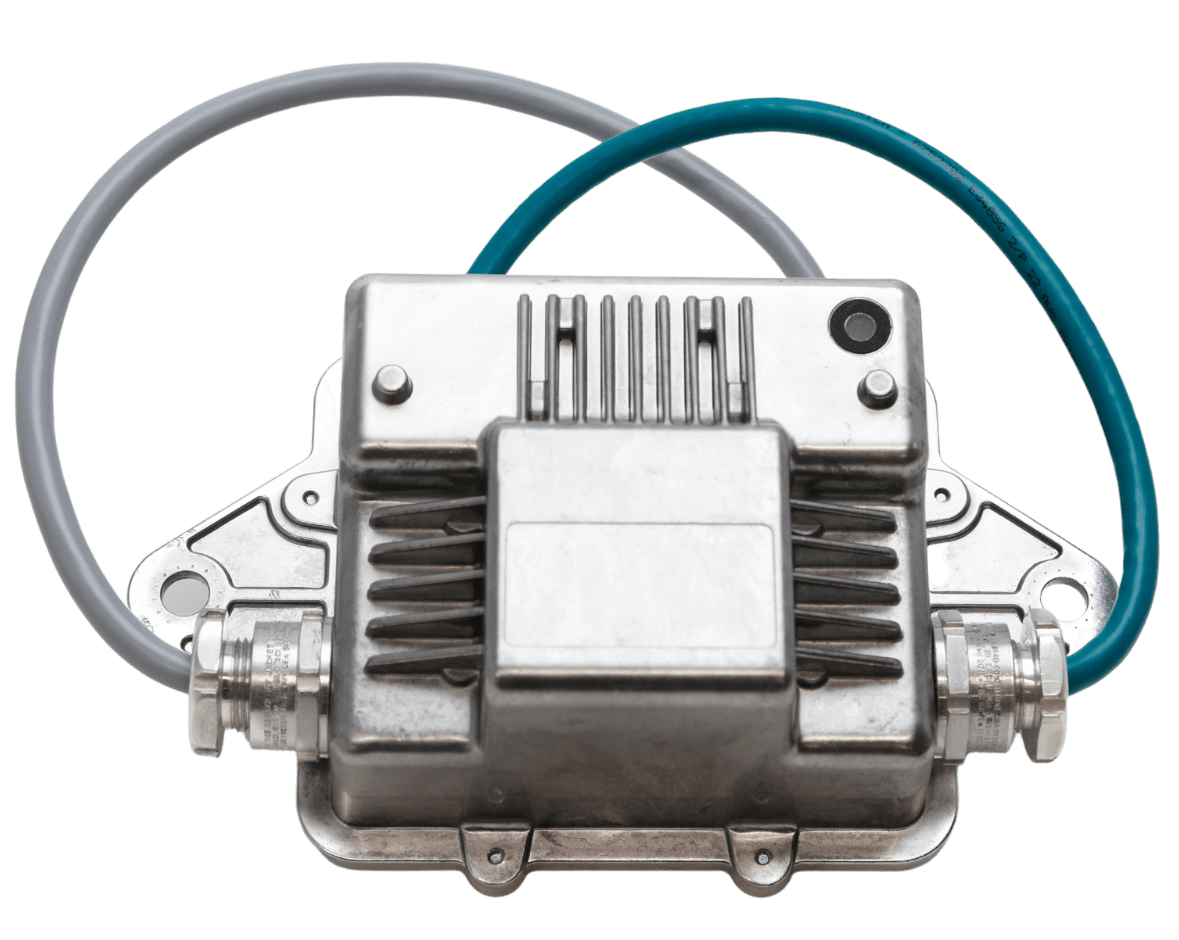

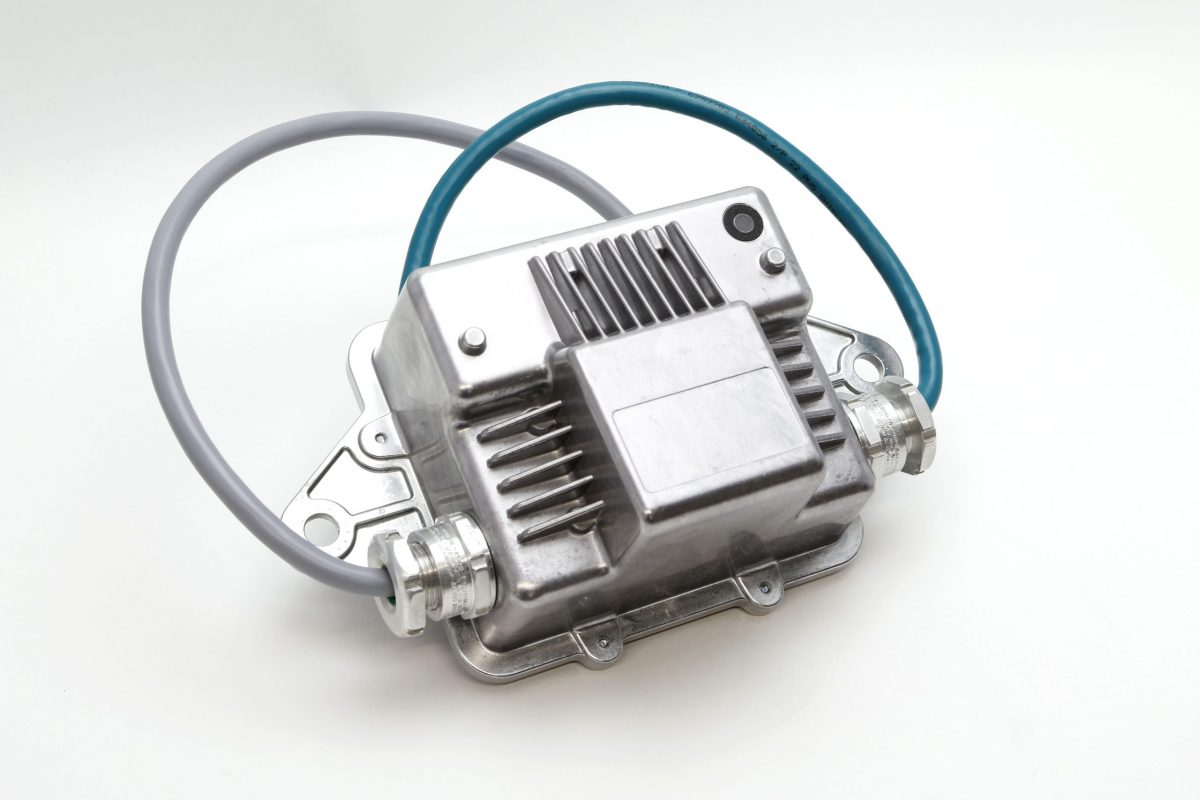

Appareo developed a grain classification sensor for a customer. This sensor, which is IEC and ATEX certified for use in explosive grain dust environments, captures images of a scene and classifies them as one of 13 different crop types, unknown, or empty. Within the sub-types of crops, the system can identify which are crops of very high similarity (e.g. confectionary vs. oilseed sunflower, red vs. white wheat, etc.). The sensor runs a custom convolutional neural network that was iteratively created to yield the optimal performance for the least computation in order to execute real-time on the camera.

In addition to developing the algorithms on the sensor, Appareo also developed the hardware and executed the explosive atmospheric certification work.

Identification of Shape Differences Among a Class of Materials

One example of this problem is the identification of strawberry shape. Strawberries that are conical are capable of being run through roller systems to align the berries in a way that they could be processed (e.g. topped by a water jet to remove the greens). Other berry shapes, such as wedges and rounds cannot be easily aligned by roller systems. Up to this point, however, it has not been possible to quickly identify one shape of strawberry versus another to enable their effective sorting during processing and packaging.

After considering a number of features that could potentially be used to discriminate between shape types, Appareo developed a deep neural network that used a combination of features that significantly outperformed the state of the art.